Introduce the jewerly laser welding machine

With its unique high-precision and high-efficiency welding advantages, 200W jewelry laser welding machine has won the favor of customers and replaced traditional processing methods. With the continuous development of laser technology, laser welding machines are increasingly used in various industries. The demand for laser welding equipment is also increasing, and laser welding is becoming the best choice for jewelry welding.And you can choose the jewelry welding machine you need.

The laser spot welding machine can mainly weld gold, silver, platinum, titanium and its alloy, electric nickel belt and other materials, can be used for jewelry, watches gossamer, integrated circuit lead all kinds of tiny, heat sensitive parts of precision welding, Devices, electronics, communications, machinery, automotive, military, gold jewelry and other industries.

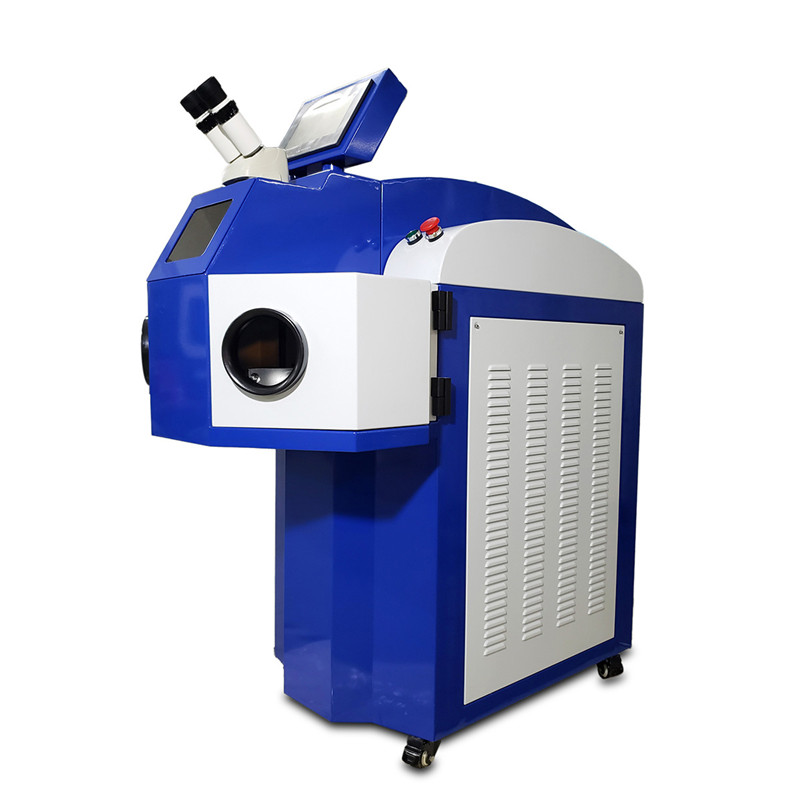

Jewelry spot welding machine with External chiller is specially developed for laser welder of jewelry by Maxwave Laser and mainly used in perforating and spot welder of gold and silver jewelry. It is of touch screen type, adopting new style power source, elaborating operation, and optimizing the optical path, with high photoelectric conversion efficiency, high stability, small size, high configuration and other characteristics.

The laser spot welding is an important aspect of laser process technology application. The spot welding process is thermal conduction, i.e. the laser radiation heats the surface of work piece, and the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool.

Desktop type laser welding machine is mainly used in the welding process of jewelry metal material, with elegant and solid welding spot, small heat-affected zone, high efficiency and low cost. It gains a wide use in microelectronics, aerospace equipment, optical communication equipment,electric vacuum devices, instruments, mechanical and electrical products,automotive manufacturing and other industries.

Compare several different appearance jewelry welding machines:

60W 40-60J

Built-in CCD system

Voltage regulating power supply

small volume

28kg 45kg (+5)

L: 510mm, M: 295mm, H: 420mm

Stainless steel 1mm, titanium nickel copper and other 0.5mm aluminum gold 0.5mm, silver cannot be welded

200W 100J

Built-in CCD system

Voltage regulating power supply

small volume

50kg 80KG (+5) 7*54*58cm

Stainless steel 1.2mm, titanium nickel copper and other 1mm aluminum gold and silver 0.5mm

200W 100J

Built-in water cooling

Regulated power supply

7*145 rod

Highest power

130kg 190KGS 1,250Wx640Dx1,520H(mm)

Stainless steel 1.5mm, titanium nickel copper, etc. 1mm, aluminum gold and silver 0.5mm

200W 100J

External water cooling

Regulated power supply

7*145 rod

Highest power

110kg 171KGS 1,250Wx640Dx1,520H(mm)

116KGS 790Wx600Dx1,120H(mm)

Stainless steel 1.5mm, titanium nickel copper, etc. 1mm, aluminum gold and silver 0.5mm

200W

Built-in water cooling

Regulated power supply

7*130rod

Small size and high cost performance

60kg 7*54*58cm 85KG (+5)

Stainless steel 1.2mm, titanium nickel copper and other 1mm aluminum gold and silver 0.5mm

200W

Built-in water cooling + external CCD

Regulated power supply

7*130rod

Small size and high cost performance

60kg 7*54*58cm 85KG (+5)

Stainless steel 1.2mm, titanium nickel copper and other 1mm aluminum gold and silver 0.5mm

The Jewerly laser welding machine applications:

This laser spot welder is mainly used for repairing holes of gold and silver jewelry, seams and claw parts. It can be applied to a variety of metals and alloys such as,

● gold

● silver

● platinum

● stainless steel

● titanium

Also can be used to repair dentures and other small parts welding such as,

● battery nickel tape

● integrated circuit leads,

● clock spring, picture tube, etc.

The heat affected zone of the welding process is narrow, and the spot size is adjustable; Smooth and clean result does not require excessive post-weld treatment;

Laser can be accurately positioned to avoid damage to jewelry.

Jewerly laser welding machine advantages:

1. High aspect ratio, thin weld width, narrow heat affected zone, zero deformation, and fast welding speed.

2. The weld is smooth and clean, with or without simple process after welding.

3. High weld strength, no porosity, eliminates the impurities of the base metal, the microstructure can be refined after welding, the weld strength is at least equal to or even exceed the base metal strength.

4. Tiny laser spot can be precisely positioned and easily automated.

5. Fit for some dissimilar metal welding.

6. Spot welding, butt welding, overlap sealing welding.

7. Various metals such as gold, silver, platinum, stainless steel, titanium, and their alloys.

8. Energy, pulse width, frequency, spot size can be adjusted within a wide range, in order to achieve a variety of welding results. Parameter adjustment lever by a closed cavity, simple and efficient.

9. Chinese best ceramic condenser cavity, corrosion resistance, high temperature, high photoelectric conversion efficiency, the condenser chamber life (8--10 years), xenon lamp life of more than 2 million times.

10. The world's most advanced automatic shading system, eliminating the time to protect the eyes.

11. With 24 hours of continuous work capacity, machine performance and stability, within 1,500 hours of maintenance-free.

12. User-friendly design, ergonomic, long working hours without fatigue.

13. Speed, high efficiency, depth, small deformation, small heat-affected zone, high quality welding, spot clean, efficient and environmentally friendly

14.2700W big water chiller allow machine work in high temperature districts,other company use 500w-1500w chiller.

15.Video tutorial help clients use machine in 10 minutes.