Description

Description:

UV flat-panel printer, also known as universal flat-panel printer or UV inkjet flatbed printer. Maxwave UV flatbed printer adopts stable platform technology and advanced stepper motor drive mode. It combines infrared meanwhile, laser positioning, water-cooling and air-cooling to meet long-term continuous work requirement. It has a wide print range and can print products within 120 mm height. Maxwave UV inkjet printer can be printed with almost unlimited material. For example mobile phone case, stone cameo, acrylic board, wallet, customized steel film, wallpaper, ceramic tile, U disk, CD-ROM, glass, ABS, PVC etc

Specifications:

Model

A3-19

Print Head

EPSON L800

UV Print Area

A3(267*420mm)

Printing Precision

2880*1440DPI

Software

AcroRIP

Printing Platform

A3(300*420mm)

Applicable System

Windows(Does not support the apple software)

Printing Speed

A3 breadth(approximately 1440dpi/3min)

Color Configuration

Support

Printing Height

0-120mm Infrared ray measurement

Relief Print

Support

Ink Consumption

1sq.m/20ml

Packing Size

L700*W700*H620mm

Ink Supply System

6-color CISS ink supply

Equipment Dimension

L670*W670*H510mm

White Ink Output

support

Net Weight

46KGS

UV Lamp Service Life

3 years

Gross Weight

66KGS

UV Lamp Cooling

Water+air cooling

Outer Packaging

The export wooden box+foam

UV Lamp Power

30W

Platform Adjustment

Touch Screen +Infrared height measurement

Platform Driver

Pulse motor driver

Voltage/Plug

AC100-230V/It is optional according to different countries

Sprinkler Protection

Intelligent infrared collision system, absorbing ink pad perservative solution anti clogging

Print Media

Phone case/leather/crystal/bottle/glass/card/CD/U-disk/name-plate ect.

Notes

Flat-panel printers adopt stable walking platform technology,leading way of stepping motor drive.

Advantages:

Motherboard

Independent research and development of CS series inkjet motherboards, small dots and high-definition inkjet effects, the German Letaishi main chip ensures the stability of the motherboard and high-precision printing processing

Electric machine

Taiwan TECO servo motor guarantees high-speed and stable printing

Frame

One-piece high-density frame, resistant to deformation and vibration

Power Board

Integrated power board imported from Japan to ensure smooth operation of the equipment circuit

wire

The whole machine is treated with PET plastic covered wire to prevent circuit chaos and static electricity

keyboard

Numerical control button panel, convenient for close operation

Emergency stop lift

External emergency stop and lifting buttons, convenient for close operation

headlight

Conducive to absorbing ultraviolet rays to achieve the best curing effect

Silent rail

Taiwan Shangyin slide rail, high precision, low noise, wear resistance, to ensure the smooth movement of the nozzle car

Synchronous belt

The American Gates timing belt wheel guarantees movement and accuracy

Spray head

Japan original EPSON nozzle

Photoelectric switch

Japan Omron photoelectric sensor switch

Switch,indicator Light

Siemens and Schneider

Platform

Aluminium structure with high flatness and strong stability

UV lamp

Imported LED lights, long life, strong curing.

Bearing

Sweden SKF imported bearings guarantee machine accuracy

Tank drag chain

IGUS mute drag chain from Germany, low noise, long life

warranty period

One year warranty for non-ink road channels and paid maintenance for life

Features:

1. The machine is designed with a flash spray and nozzle moisturizing protection plate when the nozzle is stopped; to prevent the nozzle from being blocked.

2. The software provides automatic cost calculation of consumables;

3. The machine is designed with professional channel control technology to realize individual control of each channel, providing a guarantee for ink channel technology;

4. Abundant software design functions such as feathering of printing edges, automatic correction of left and right errors, deviations, and white jumps;

5. Provide powerful and comprehensive hardware detection and adjustment functions, such as nozzle turntable, nozzle position calibration, nozzle voltage adjustment, and bidirectional printing calibration.

6. Easy-to-use menu-style operation control makes it easier for the operator to get started;

7. Smart wave printing technology: Smart wave printing technology greatly improves the banding and pass phenomenon in traditional printing methods; in order to output high-quality products.

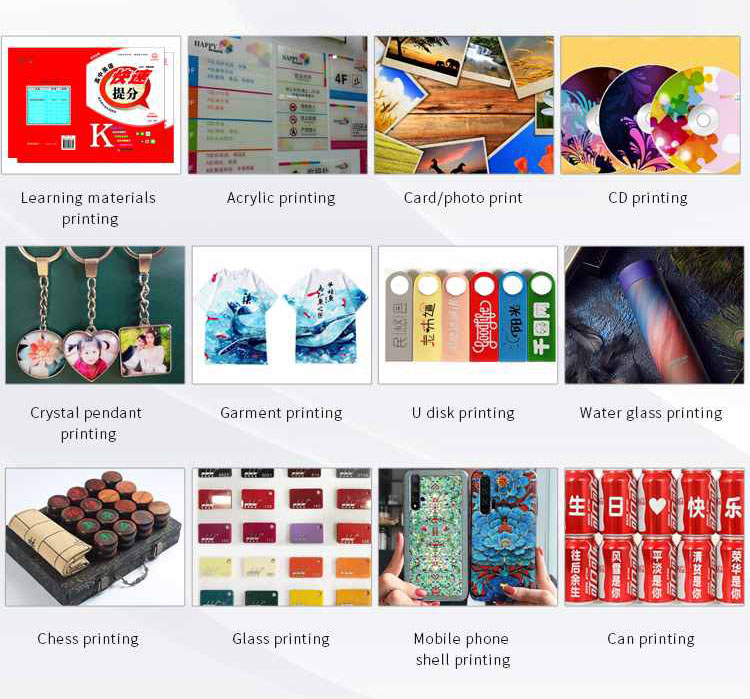

Sample:

Service:

1. Core technology. When we were a small factory, we have focused on the development of core components such as laser power supplies and optical path. Unlike other suppliers, they only sell through assembly equipment.

2. Independent research and development department. This means we can offer our customers customized machines and improve the equipment according to market changes.

3. Dealer support plan. In the early stage of customers' market development, we provide technical parameters for the installation and use of equipment free of charge, share good marketing methods, help customers win the market and achieve success.

4. Strict testing. All of the suppliers we work with come from world-class manufacturers. Before the delivery, each machine needs to be tested and inspected for 48 hours (marking machine, welding machine) and 4-7 days (cutting machine) to ensure quality and safety.

5. Timely delivery. Each machine has an accurate assembly process and strict time control to ensure that customers receive goods in a timely manner.

6. After-sales service and guarantee. We offer a 2-year warranty and any problems occur during the period and we have a responsibility to resolve them. If any part of the machine is broken, we will repair it for free and send free accessories.