Description

Description:

Maxwave Fiber laser marking machine adopts international the most advanced fiber laser technology and it's the most popular marking machine in recent years, no consumables, 100,000 hours maintenance-free.It's applicable to all kinds of metal & engineering plastics, such as MS, SS, aluminum, ceramics, PVC, ABS, PE, etc. It’s widely used for electronic components, hardware, daily consumer goods, sensors, auto parts, 3C electronics, crafts, precision apparatuses, gifts and ornaments, medical equipments, bathroom accessories, packaging industry, battery industry, IT industry, etc.

Specification:

Laser Power

20W/30w/50w/75w/100w

Working Area

110*110mm / 150*150mm/175*175mm / 200*200mm/300*300mm

Cooling Mode

Air Cooling

Laser Wavelength

10.64um

Response Time

0.5ms

Frequency of puMaxwavee

20-100KHz

Marking Depth

≤0.4mm

Marking Speed

≤7000mm/s

Marking Lines

1-10 lines

Minimum Line Width

0.01mm

Minimum Character

0.15mm

Repeatability Accuracy

±0.002mm

Resolution Ratio

0.1mm

Marking Content

Text, pattern, date, bar code, etc

Operation System

Microsoft Windows 7

Control Software

EZCAD Control Software

Graphic Format Supported

BMP, JPG, GIF, TGA, Ai, DXF, PLT, PNG, TIF, ai, DXF, DST, etc.

Unit Power

≤1.2KW

Operation Temperature

5°C-40°C

Relative Moisture

≤ 90%, no fog

Supply Voltage

220V/50Hz

Advantages:

1.Desktop Fiber Laser marking machine Fast marking Speed and High Efficiency

2.High Electro-optic Conversion Efficiency

3.Perfect marking effect

4.Integrated structure,small and compact size,less occupied area,easy transportation

Feature:

1. Maintenance free,for longterm consideration, the cost is much lower than other laser marking machine, save equipment and worker cost.

2. High speed, 2-3 times over than traditional diode pumped marking machine.

3. Using advancesd laser module(Raycus or IPG brand), the life time can up 100,000 hours.

4. With red light positioning device, more accurate and reduce positioning time.

5. Perfect performance, 24 hours continuous working ability.

6. Simple and convenient operation, easy to learn and operate.

7. Compatible AutoCAD,Corel Draw,Photoshop and etc, support bmp,jpg,gif,tga,png,tif,ai,dxf, dst,plt formats file.

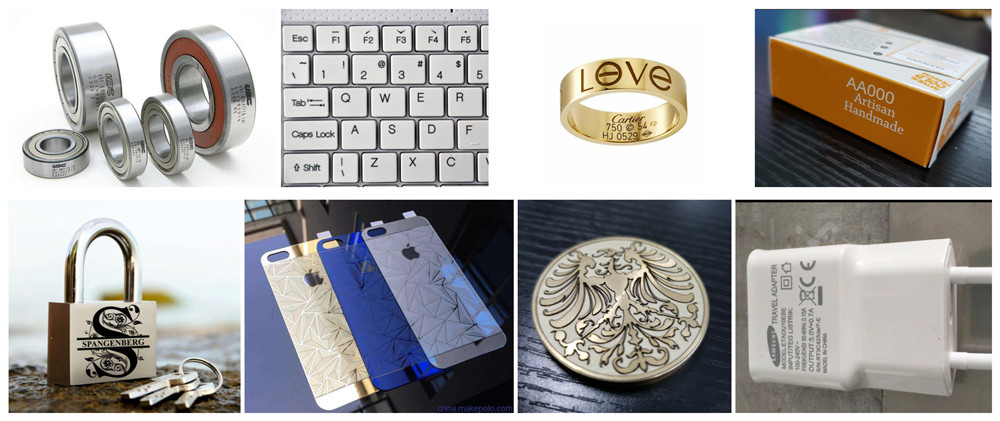

Sample:

Service:

1. Core technology. When we were a small factory, we have focused on the development of core components such as laser power supplies and optical path. Unlike other suppliers, they only sell through assembly equipment.

2. Independent research and development department. This means we can offer our customers customized machines and improve the equipment according to market changes

3. Dealer support plan. In the early stage of customers' market development, we provide technical parameters for the installation and use of equipment free of charge, share good marketing methods, help customers win the market and achieve success.

4. Strict testing. All of the suppliers we work with come from world-class manufacturers. Before the delivery, each machine needs to be tested and inspected for 48 hours (marking machine, welding machine) and 4-7 days (cutting machine) to ensure quality and safety.

5. Timely delivery. Each machine has an accurate assembly process and strict time control to ensure that customers receive goods in a timely manner.

6. After-sales service and guarantee. We offer a 2-year warranty and any problems occur during the period and we have a responsibility to resolve them. If any part of the machine is broken, we will repair it for free and send free accessories.