Common problems of laser welding machine

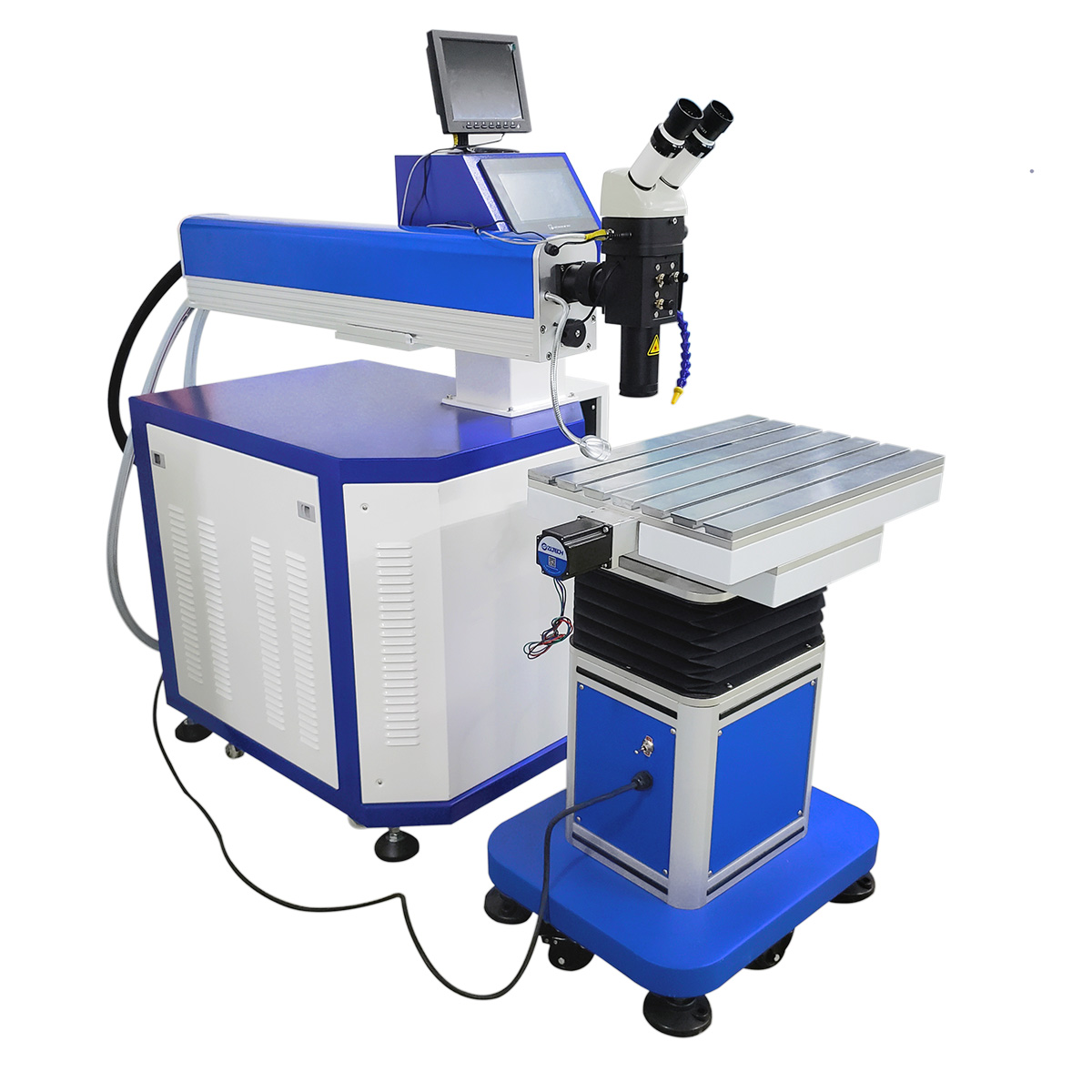

Basic composition of laser welding machine

(1) Laser source: fiber laser and YAG laser

Main features of fiber laser:

Continuous welding (customers need sealed welding and continuous light emission); the same power and lower energy as YAG; life is more than 100,000 hours without consumables.

The main features of YAG laser:

Spot welding; the price is lower and the energy is stronger under the same power; there are xenon lamp protection lenses and other consumables.

(2) Control system:

Basic system: Only the energy and focal length of the laser can be adjusted, and the light can be emitted from the foot.

CNC system: In addition to adjusting the energy of the laser, it can be programmed to automatically move and emit light.

(3) Console:

Manual stage: select the direction of the handwheel to adjust the stage in the XYZ axis.

Electric stage: through the joystick or button console, it automatically moves in the XYZ axis direction.

Automatic table: The table will automatically move according to the position input by the computer CNC software.

(4) Welding space:

Boom welding: The light path can be lifted and rotated greatly. Suitable for large metal parts that are difficult to move.

Advertising welding: The optical path is equipped with a large table, suitable for flat advertising characters.

Hand-held welding: does not require high precision, manual welding. Suitable for welding of metal parts of any size and shape, mainly kitchen and bathroom doors and windows, metal shells, advertising characters, etc.

Optical fiber/YAG automatic welding, suitable for large and standardized small and medium-sized metal parts.

Die welding: Small and medium-sized metal parts suitable for manual welding. The space can be enlarged by removing the table.

Jewelry welding: only suitable for manual welding of precision small metal parts such as jewellery, glasses, watches, denture trays and other dental metal parts.

(5) Others: chiller/CCD, microscope, optional rotation axis.

Choose the right welding machine according to different needs

(1) What is the required depth of welding? (Determine the power of the machine, maximum)

YAG 60W: Stainless steel (SS) 0.5mm

YAG 200W: Stainless steel 1.2mm, titanium nickel copper and other 1mm aluminum gold and silver 0.5mm

YAG 300W single lamp (actual 260W): stainless steel 1.5mm

YAG 300W double lamp: stainless steel 2mm

YAG 400W: Stainless steel 2-2.5mm

YAG 500W: Stainless steel 3mm

Fiber500W: SS 1-1.5mm

Fiber1000W: SS 2.5mm

Fiber 1500W: SS 3mm

Fiber2000W: SS 4mm

Learn more about laser welding machine:

The properties of laser welding give an advantage over other forms of welding that can exploit in several ways:

1.Precision parts: Lasers are excellent for welding fine and delicate metal components and generating minimal internal stresses due to the minimal heat input.

2.Medical devices: Non-contact welding and no welding splatter ensures hygiene when welding medical devices.

3.Aesthetics: Laser welding finishes are excellent.

4.Solenoids and machined items: Lasers for joining machined components such as solenoids, and create minimal distortion due to the low heat input.

5.Limited access: The non-contact laser beam permits welding in otherwise inaccessible areas.

6.Jewerly welding and high-value items: The precise controllability and negligible heating effects make it a good choice for welding high value, high precision parts including precious metals.

Do you know the process parameters of laser welding machine?

(1) Power density.

Power density is one of the most critical parameters in laser processing.With a high power density, it can heate the surface layer to the boiling point within a microsecond time range, resulting in a large amount of vaporization.

Therefore, high power density is advantageous for material removal processes such as punching, cutting, and engraving. For lower power density, it takes several milliseconds for the surface temperature to reach the boiling point.Before vaporize the surface layer, the bottom layer reaches the melting point, which is easy to form a good fusion weld.

Therefore, in conductive laser welding, the power density is in the range of 10 ^ 4 ~ 10 ^ 6W / CM ^2.

(2) Laser pulse waveform.

The laser pulse waveform is an important problem in laser welding, especially for thin-plate welding. When a high-intensity laser beam is irradiated to the surface of the material, 60 ~ 98% of the laser energy is reflected and lost on the metal surface, and the reflectance changes with the surface temperature.During a laser pulse, the reflectivity of the metal varies greatly.

(3) Laser pulse width.

Pulse width is one of the important parameters of pulse laser welding. It is not only an important parameter different from material removal and material melting but also a key parameter that determines the cost and volume of processing equipment.

(4) The influence of defocus amount on welding quality.

Laser Welding Machine usually requires a certain amount of defocus, because the power density in the center of the spot at the laser focus is too high, and it is easy to evaporate into holes.

The power density distribution is relatively uniform across the planes away from the focal point of the laser. There are two ways of defocusing: positive defocus and negative defocus.

The focal plane is above the workpiece for positive defocus, otherwise it is negative. According to geometrical optics theory, when the positive and negative defocus planes are equal to the welding plane, the power density on the corresponding planes is approximately the same, but the shape of the molten pool obtained is actually different.

With negative defocus, it can obtain greater penetration , which is also have relation with formation of the molten pool. Experiments show that laser heating of 50 ~ 200us material begins to melt, forming liquid metal and partial vaporization, forming high-pressure steam, and ejecting at extremely high speed, emitting dazzling white light.

At the same time, the high-concentration vapor moves the liquid metal to the edge of the molten pool, forming a depression in the center of the molten pool. When negative defocusing, the internal power density of the material is higher than the surface, and it is easy to form stronger melting and vaporization, so that the light energy is transmitted deeper into the material.

Therefore, in practical applications,if need large penetration depth, we can use negative defocus; when welding thin materials, it need to use positive defocus

(5) Welding speed.

The speed of the welding speed will affect the heat input per unit time.

If the welding speed is too slow, the heat input will get too large, which will cause the workpiece to burn through.If the welding speed is too fast, the heat input will get too small, which will cause the workpiece to get opaque.

Compare mold welding/advertising welding/cantilever welding machine:

The advertising word welding machine generally only CCD does not need to rotate and the microscope has XYZ axis stage.

The boom welding machine is equipped with CCD, electric lifting shaft, and rotating shaft (welded pipe). 360 degree rotating boom.

(1) The difference in welding depth (different power)

(2) Applied to metal parts with different sizes and appearances.

Die welding: suitable for manual welding of some small and medium-sized metal pipes, and metal pipes can be welded by rotating shafts.

Metal components that do not need automatic welding can be welded with a mold, as long as the table is placed down.

Advertising welding: special welding advertising words.

Boom welding: It can be regarded as a longer and higher version of die welding, and the welding machine has a larger moving range. Suitable for manual welding of large metal devices.