Description

Description:

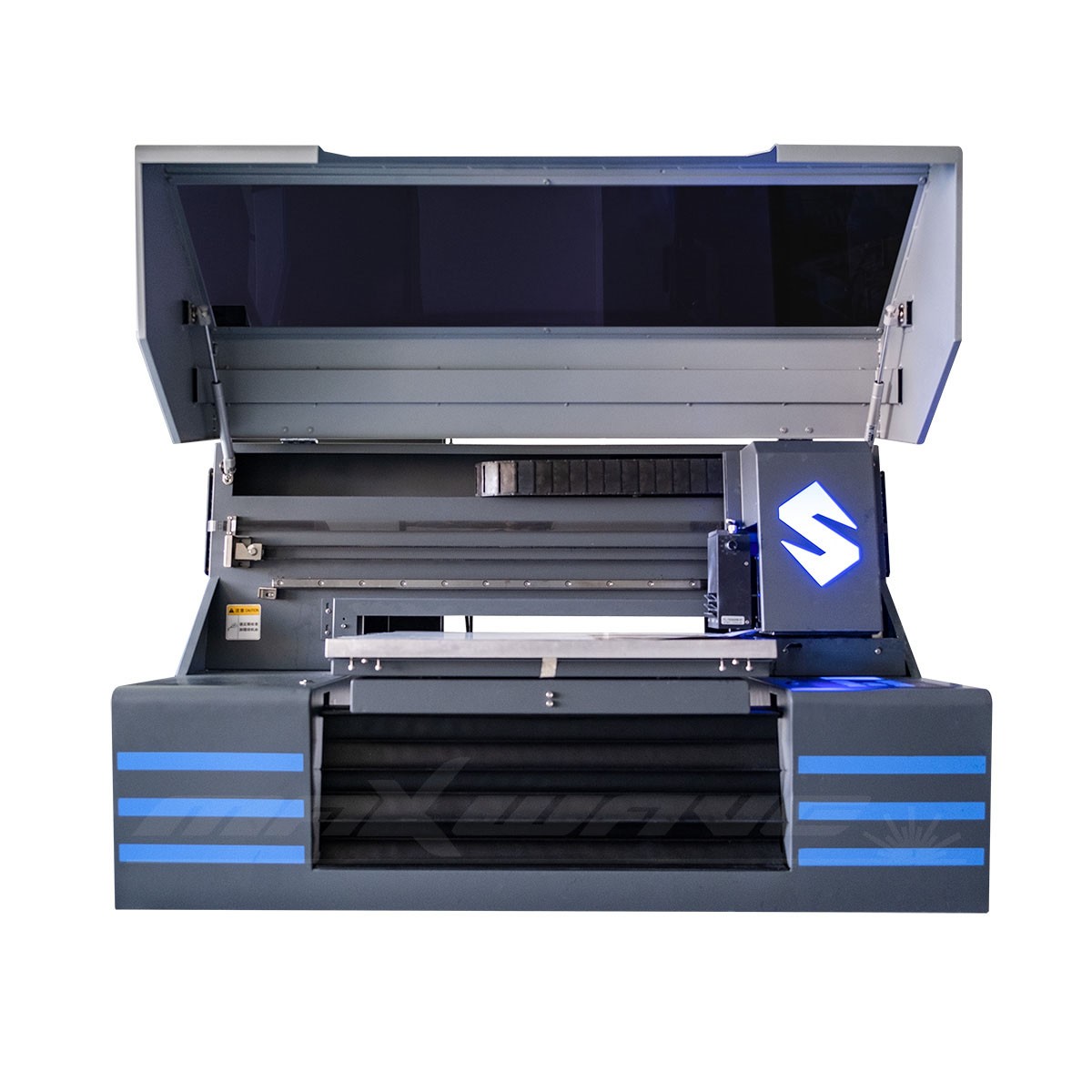

Maxwave Laser is a professional manufacturer of high quality and high accurancy uv printing machine . Professional and excellent team and advanced production technology is our guarantee of quality products. This digital flatbed UV printer is the latest UV machine of our company. This model is designed for industrial bulk production with high printing speed,which can print on almost any material directly. With UV light irradiating during printing procedure,images on object surface are dry fast and scratch resistance.

Specifications:

Print Size

500(W)*400(L)mm

Nozzle configuration

Japan's latest EPSON original 180 holes×8 rows/print head, ink droplet

variable technology, maximum ink drop 12pl, minimum 2.5pl

Number of nozzles

1 or 2 nozzles (optional)

Print color

High-precision intelligent dual 4-color (CMYK) (double nozzle

eco-solvent), 8 colors (double nozzle eco-solvent), white ink W+CMYK 4 color ink (double nozzle UV ink) (optional color configuration according to the nozzle)

Print height

150mm

Lifting function

Intelligent platform lifting

Printing accuracy

2880dpi*1440dpi*720dpi*360dpi

Ink system

1L×4 colors / 220ML×8 colors, uninterrupted intelligent circulating

continuous supply system

Print Speed

CMYK (single head four colors) CMYK+W (1 print head prints 4 colors +1 print head prints white ink) 2×CMYK (double four colors) (2 print

heads print 4 colors at the same time)

720×720dpi/4Pass 8 ㎡/H

1440*720dpi/8Pass 4 ㎡/H

1440*1440dpi/16Pass 2 ㎡/H

2880*1440dpi/32Pass 1.8 ㎡/H

Receive files

TIFF (RGB&CMYK), BMP, PDF, EPS, JPEG, AI, PSD, etc.

Electricity requirements

AC220/110±10,50HZ~60HZ, P 100W

Interface method

High-speed USB transmission interface

Operating platform

MicrosoftWindows98/Me /2000 /XP/Win7/win10

Software output

Color management software UltraPrint imported from Germany

working environment

The best temperature: 15℃-35℃, relative humidity 20%-80%

equipment weight

70KG

Equipment size

1000 x750 x650 mm (length x width x height)

Advantages:

The front cover

Black brown front cover prevents high-intensity UV stimulation, protects glasses and body contact

Side cover

The floating side cover is conducive to long-term operation and cooling of the equipment, avoiding high-temperature short circuit of the circuit

Material thickness

150MM printing height is suitable for most high thickness materials

Ink tank

Adopt a fixed enveloping design to prevent ink leakage when the equipment is moved or ink is added

Nozzle bottom

plate

The ring is fixed, no need to screw on the inside of the nozzle, to avoid the problem of inaccurate alignment or color cast when replacing the nozzle

X axis operation

The integrated structure of parallel stretching with teeth is conducive to ink breakage during the printing process

Y axis operation

Double SBK sliding, four TB sliding blocks interlock, keep the equipment stable when moving forward and backward

Automatic ink

extraction system

Sliding ink stack, independent ink pump, strong sealing, built-in emergency ink pump

Waste ink tank

Integrated waste ink tank, convenient to collect waste ink for disposal

Operator guidance

Complete video tutorials and 24-hour manual one-to-one service, professional installation process guidance and training until the customer’s operators will be proficient in operation

Features:

1.Not subject to batch restrictions, one from India, and not because of small quantities,and increase the cost of a single piece.

2.Relief effect: relief print, print through the white ink, highlight the special effects of relief,so that the product value is higher.

3.The complexity of the pattern without any restrictions, full color gradient can be printed once completed, the machine automatically color.

4.The effect of printing realistic, bright colors.

5.Pattern waterproof, anti-UV, do not fade.

6.Simple, simple computer operators can easily grasp, save labor costs.

7.The whole process of environmental protection, no pollution, harmless to the environment.

Sample:

Services:

1. Core technology. When we were a small factory, we have focused on the development of core components such as laser power supplies and optical path. Unlike other suppliers, they only sell through assembly equipment.

2. Independent research and development department. This means we can offer our customers customized machines and improve the equipment according to market changes

3. Dealer support plan. In the early stage of customers' market development, we provide technical parameters for the installation and use of equipment free of charge, share good marketing methods, help customers win the market and achieve success.

4. Strict testing. All of the suppliers we work with come from world-class manufacturers. Before the delivery, each machine needs to be tested and inspected for 48 hours (marking machine, welding machine) and 4-7 days (cutting machine) to ensure quality and safety.

5. Timely delivery. Each machine has an accurate assembly process and strict time control to ensure that customers receive goods in a timely manner.

6. After-sales service and guarantee. We offer a 2-year warranty and any problems occur during the period and we have a responsibility to resolve them. If any part of the machine is broken, we will repair it for free and send free accessories.