Description

Description:

With its unique high-precision and high-efficiency welding advantages, 200W jewelry laser welding machine has won the favor of customers and replaced traditional processing methods. With the continuous development of laser technology, laser welding machines are increasingly used in various industries. The demand for laser welding equipment is also increasing, and laser welding is becoming the best choice for jewelry welding.

The laser spot welding machine can mainly weld gold, silver, platinum, titanium and its alloy, electric nickel belt and other materials, can be used for jewelry, watches gossamer, integrated circuit lead all kinds of tiny, heat sensitive parts of precision welding, Devices, electronics, communications, machinery, automotive, military, gold jewelry and other industries.

Specification:

|

Laser |

Nd3+:YAG |

|

Wave length |

1.064mm |

|

Output power |

200W |

|

Pulse width |

0.2~15ms adjustable |

|

Frequency |

1~20Hz adjustable |

|

Single pulse energy |

100-150J |

|

Max output power |

4kw |

|

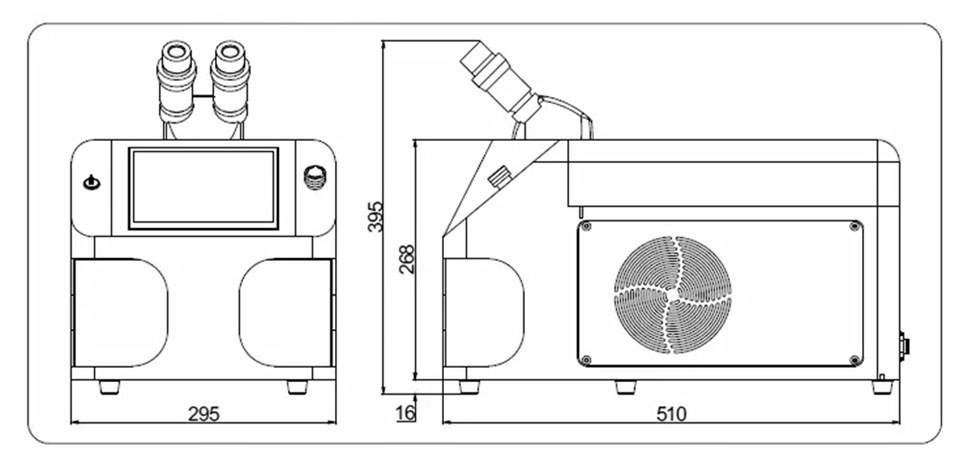

Machine size |

75.5*40*45cm |

|

Main parts |

Brief describing |

|

Laser |

Φ7 superior YAG crystal, ceramic focus cavity |

|

Laser power supply |

LS-W60 pulse power supply |

|

Special Cooling System |

Unitization special chiller,over temperature alarming,flow protecting。 |

|

Control System |

Singalchip(pic) |

|

Viewing System |

10X microscope viewing system |

Laser medium: Nd3+:YAG Wavelength: 1.06mm Pump lamp: pulsed Xenon lamp

Pulse frequency: 0~15Hz adjustable Pulse width: 0.2~15ms adjustable

Energy of the single pulse: 0~100 J Laser power: 60w

Advantages:

1). Energy, pulse width, frequency, spot size can be adjusted within a wide range, in order to achieve a variety of welding results. Parameter adjustment lever by a closed cavity, simple and efficient.

2). Chinese best ceramic condenser cavity, corrosion resistance, high temperature, high photoelectric conversion efficiency, the condenser chamber life (8--10 years), xenon lamp life of more than 2 million times.

3). The world's most advanced automatic shading system, eliminating the time to protect the eyes.

4). With 24 hours of continuous work capacity, machine performance and stability, within 1,500 hours of maintenance-free.

5). User-friendly design, ergonomic, long working hours without fatigue.

6). Speed, high efficiency, depth, small deformation, small heat-affected zone, high quality welding, spot clean, efficient and environmentally friendly

7).2700W big water chiller allow machine work in high temperature districts,other company use 500w-1500w chiller.

Features:

1.Laser is high precision (0.1-2mm spot size)welding methold and laser beam is very thin.

2.Laser is quick, Frequency can reach 20HZ.

3.Jewelry,glasses frame,mould,dental teeth need laser welding way which have beautiful welding joints .

4.Jewelry Laser welding machine is widely used in all kinds of metal like gold,sillver,bronze,aluminum.steel and titanium!

5.Laser welding is new product, Buying this product can help you win advanced cleaning market!

6.We manufacture power supply which have big advantage in prices and after sale service.

7.Engineer door to door service.

Sample:

Service:

1. Core technology. When we were a small factory, we have focused on the development of core components such as laser power supplies and optical path. Unlike other suppliers, they only sell through assembly equipment.

2. Independent research and development department. This means we can offer our customers customized machines and improve the equipment according to market changes

3. Dealer support plan. In the early stage of customers' market development, we provide technical parameters for the installation and use of equipment free of charge, share good marketing methods, help customers win the market and achieve success.

4. Strict testing. All of the suppliers we work with come from world-class manufacturers. Before the delivery, each machine needs to be tested and inspected for 48 hours (marking machine, welding machine) and 4-7 days (cutting machine) to ensure quality and safety.

5. Timely delivery. Each machine has an accurate assembly process and strict time control to ensure that customers receive goods in a timely manner.

6. After-sales service and guarantee. We offer a 2-year warranty and any problems occur during the period and we have a responsibility to resolve them. If any part of the machine is broken, we will repair it for free and send free accessories.